Production capacity : 150 kg per hour

Body material: made of stainless steel 304 (suitable for food products)

Number of required packaging machines: 3 machines

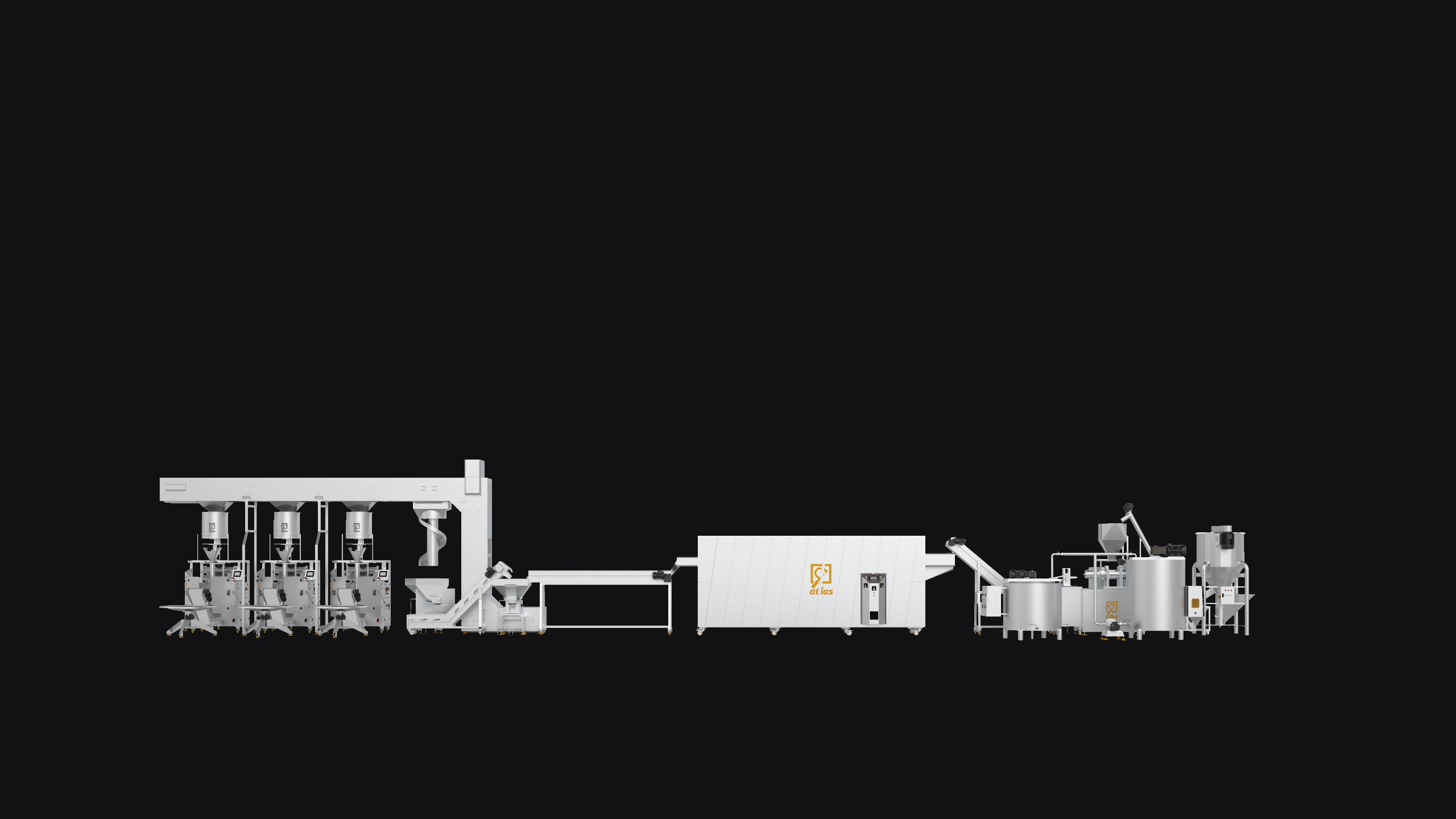

Line Sections

Corn Blender

Function: mixing and hydrating corn

Spiral Conveyor

Function: Transferring the Materials spirally from the corn blender to an extruder

Extruder

Model: ATLAS EXTRUSION 2020

Production Capacity: 150 Kg/h

Chocolate Cookıng Tank

Capacity: 600 kg

Function: The tank is designed as a double jacket from which the water is heated via the electric resistances to facilitate melting and mixing of the chocolate.

Storage and stuffing Mixer

Capacity: 500 kg

Function: The tank is designed as a double jacket from which the water is heated via the electric resistances to facilitate melting and mixing of the chocolate.

stuffed corn figer cutter

Control of the length of the sticks and fingers of chips with an inverter that controls the speed of the knife

Conveyor:

Function: transferring stuffed corn chips to oven

Drying Oven:

Function: roasting and drying corn chips and fully extracting humidity

Working System : Customized

1- Diesel system (Riello Italy)

2- Gas system (Riello Italy)

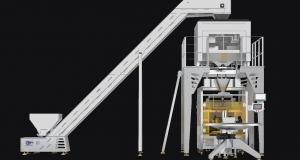

Conveyor Line (Z-shape)

Function: feeding packaging machines

Working system: Fully Automatic

Filling and packaging volumetric machine: (3 machines)

The machine is made of stainless steel 304 (suitable for food products)

It consists of: structure - filling device - internal system - external protection - feeding device

Working system: mechanical

Holds quality certificates and

ISO 9001 - ISO 18001 - OHSAS 18001

And the European product quality certificate CE

For more details, please contact us for a quotation