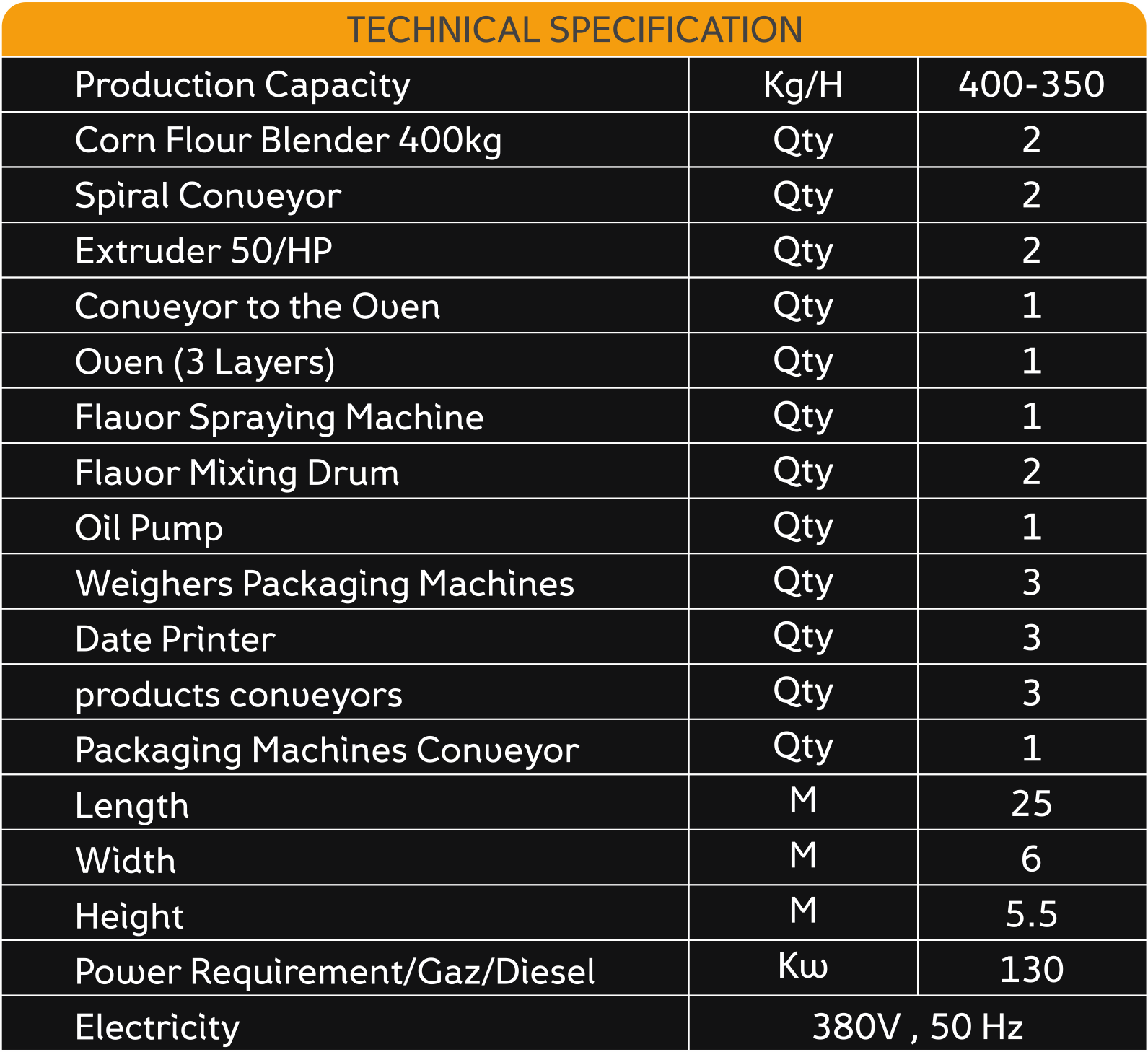

Production capacity : 350 - 400 kg per hour

Body material: made of stainless steel 304 (suitable for food products)

Number of required packaging machines: 3 machines

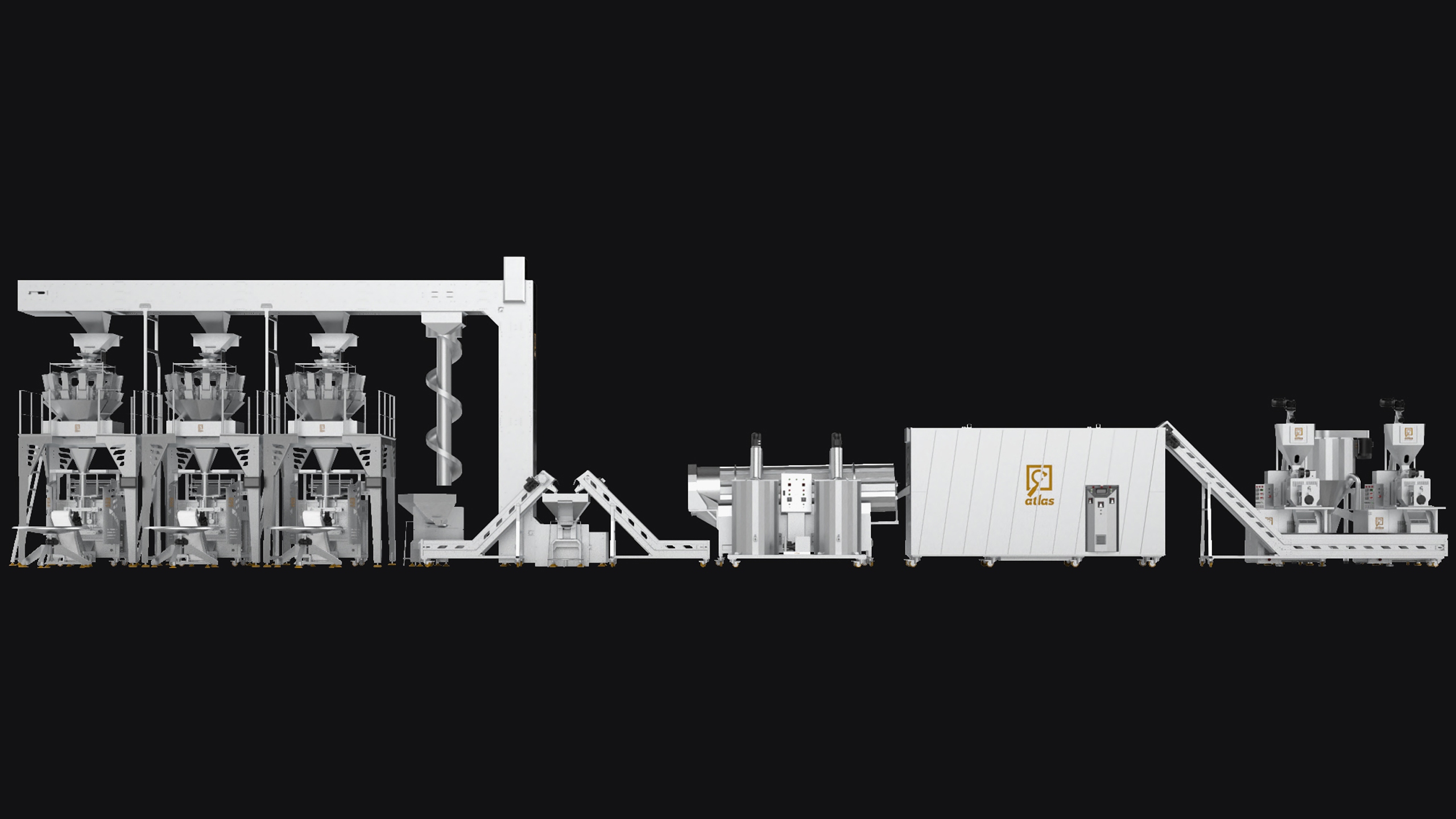

Line Sections

Double Corn Blender

Function: mixing and hydrating corn

Double Spiral Conveyor

Function: Transferring the Materials spirally from the corn blender to an extruder

Double Extruder

Model: ATLAS EXTRUSION 2020

Production Capacity: 350- 400 Kg/h

Depending on the type of raw materials, the amount of flavor added and also the thickness of the grain

The extruder can produce up to 40 shapes of chips

Conveyor or Air blower :

Function: Transferring the Materials from the extruder to an oven

Drying Oven:

Equipped with 3 layers conveyor

Function: roasting and drying corn chips and fully extracting humidity

Working System : Customized

1- Diesel system (Riello Italy)

2- Gas system (Riello Italy)

Flavorer (Flavor mixing drum)

Function: spreading homogeneous mixture of oil and flavor on the outside of the chips.

Double oil & Flavor Blender

Function: Mixing oil with flavor and spraying it indsie flavor drum

Capacity: 400 Liters per tank

Oil pump

Function: Pumping the flavor with oil from blender to drum

Conveyor Line (Z-shape)

Function: feeding packaging machines

Working system: Fully Automatic

Filling and packaging weighing machine: (3 machines)

Filling system: Two towers of 14 weighing units from (High Dream) company with high specifications

Weighing system: It works from (10 - 1000) grams with high precision and conforms to European specifications

The machine is made of stainless steel 304 (suitable for food products)

It consists of: structure - filling device - internal system - external protection - feeding device

Work system: mechanical - air - servo

Holds quality certificates and

ISO 9001 - ISO 18001 - OHSAS 18001

And the European product quality certificate CE

For more details, please contact us for a quotation